- September 16, 2024

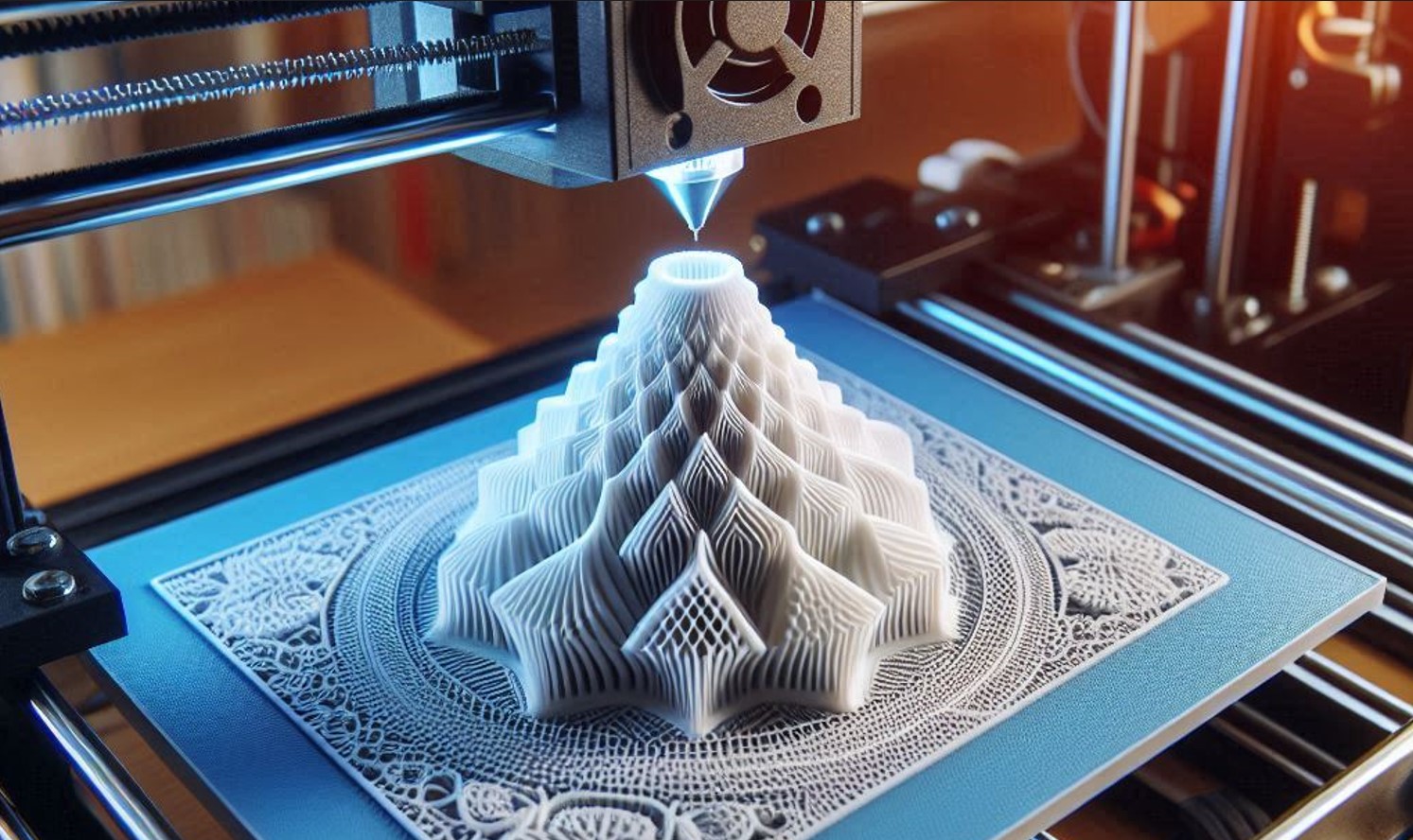

3D Printing Trends in 2024

3D printing is one of the fastest-growing manufacturing methods. It is currently used in every field of production – from construction materials to consumable arts, and 3D printing trends vary from one industry to another.

In the 3D printing technologies for mass manufacturing, we see tangible developments year by year. Due to the flexibility it provides, this printing method is used more widely than ever, with a 21% growth in 2020 compared to 2019. Looking to summarize the statistics of 2021, we can already be positive that the future of online printing is more promising than ever before.

Commercial and Industrial usage of 3D printing

3D printing has been revolutionary in both limited and mass production due to its affordability and rather more flexible qualities as opposed to traditional means of production. The list of industries that use 3D printing includes but is not limited to:

- Aerospace

- Robotics

- Metal manufacturing

- Architecture

- Medical

- Education

- Gaming

- AR/VR

As 3D printing trends change and develop, the future of 3D printing outlines more and more industries that it can be beneficial to.

What sets 3D printing apart from every other production type is the way you can easily change the schemes and designs at every level of production. Traditional technologies can never be as cost-effective when it comes down to shorter cycles of production since the entire equipment must be altered for the tiniest changes in the final product.

With 3D printing, both high-volume and low-volume manufacturing become as flexible as they have ever (never) been before. Low-volume manufacturing benefits from this technology since the traditional, complex production lines used to make the costs jump so high that the final product didn’t always meet the market expectations. The technology enables the creation of parts with specified attributes such as water repellency, increased strength, and heat resistance using customized materials.

The key advantages of 3D printing are rapid prototypes. Because 3D printing speeds up the prototyping process, items can be made in the quickest period feasible. Users can change designs in any way they choose with 3D printing, allowing them to create unique and personalized new parts. In comparison to traditional production methods, 3D printing allows manufacturers and engineers to build more intricate and complicated designs as many subtractive processes have design limitations, but 3D printing does not.

3D printing technology does not require additional room for inventory storage. This is because there is no need to print in bulk unless it is absolutely necessary; hence, costs and space are saved.

3D printing statistics

Statistics are there to back up the belief that the future of 3D printing is in every industry that involves any kind of manufacturing. Not only the market of 3D-printed objects and products, but also the 3D printing equipment and materials market is growing faster than ever.

According to Statista, the global market for 3D printing products and services was estimated to be worth $12.6 billion in 2020. And the numbers are still growing. As far back as in 2017, 3D printing was already an integral part of prototyping in 60% of automotive companies. In healthcare, the 3D printing market was valued at $1,036.58 million in 2020, according to Allied Market Research. In every single industry, the share of 3D printing is growing at an unpredictable rate.

How 3D modeling is used in 3D printing

3D printing is very different from any other manufacturing technology, and this is why you have to pay extra attention to the way you design any item.

Depending on the particular 3D printing process you’re using, different approaches are required.

For fused deposition modeling (FDM), you need to design one of the sides large and flat so the item “sits” on that side. Plus, there should be no detached, floating or hanging details, since every part is supported by the “foundation”.

Stereolithography (SLA), though not as widely used as FDM, gives you more freedom in terms of design. Since the objects printed with SLA are entirely or partially hollow, you need to design a couple of drainage spaces in order to get rid of the residual rezin after the object solidifies.

Selective laser sintering (SLS), more similar to SLA than to FDM, offers a higher level of support and thus allows you to design lighter objects with more unsupported parts and never worry about the durability.

These technical requirements come before all 3D printing trends and must be considered thoroughly for you to get the perfect final result.

The future of 3D printing

With all the information we have, we can surely state that 3D printing is the future of all manufacturing. It’s certainly no longer a luxury and the production costs have declined so much that it’s often much more affordable than any traditional manufacturing process.

Still waiting for a 2022 summary, we already have quite some predictions for the coming years.

According to Smart Tech Analysis, new studies predict up to $3.2 billion growth in the 3D printing industry by 2022. Another report, cited on 3dprintingindustry.com, estimates the market value to be $37.2 billion in 2026.

Conclusion

Whichever industry you are in, there’s one simple fact: 3D printing is taking over. Instead of questioning whether it’s time we start using it in our business, the questions must stand as follows: which 3D trends should we follow primarily, when will it be most cost effective to switch the entire production to 3D printing, and what more can we get out of this technology?

This is the perfect moment to start diving into every single technical information that we can get on 3D printing and apply it in the nearest future.