- April 6, 2023

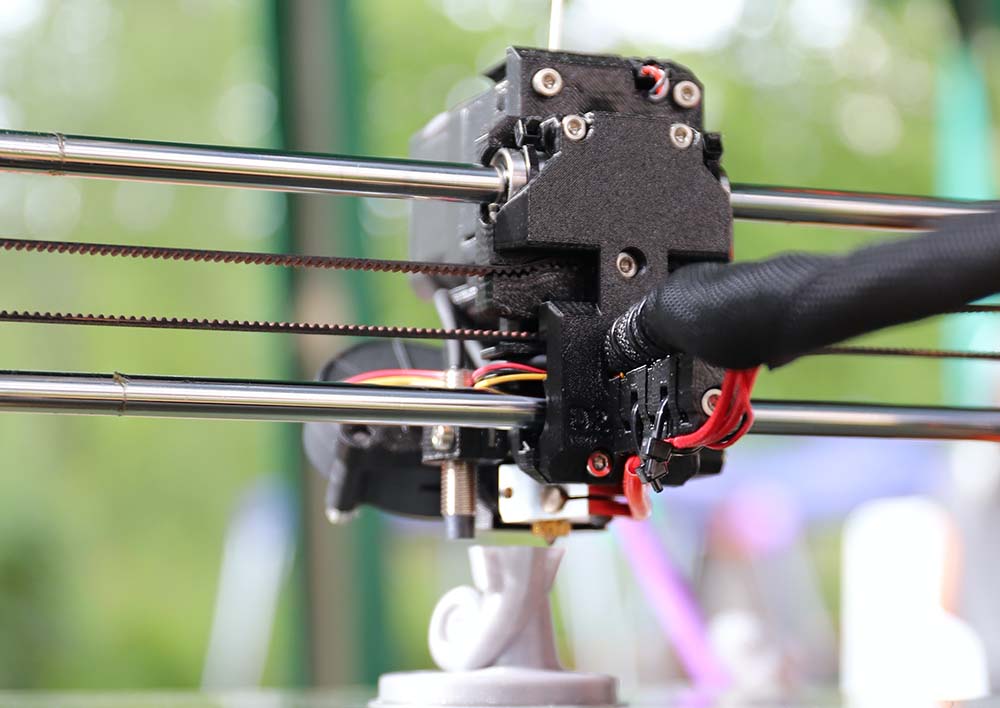

Fictiv launches 10 new materials for Advanced 3D Printing

Fictiv, the custom manufacturing operating system, has recently expanded its online quoting platform with 10 additional materials for 3D printing, which are ideal for more complex prototyping requirements. These newly added materials can be instantly quoted, providing dynamic pricing, lead time, and feedback on manufacturability, and customers can receive their parts as quickly as within 24 hours.

Fictiv aims to simplify the process of sourcing custom parts for its customers. With the introduction of this range of sophisticated 3D printing materials, available through its swift online service, engineers and purchasers can cut down on ordering time by several days when compared to traditional manufacturing.

The ordering process for 3D printed parts via Fictiv is self-service and can be completed within minutes. Customers have the option to seek consultative guidance from an expert as well. This enhances overall project efficiency. Moreover, every order is matched with a highly-qualified manufacturing partner to ensure dependable quality.

These new materials are versatile and can be utilized across a broad range of applications in various industries such as automotive, industrial, consumer products, and medical sectors. They are suitable for creating concept models, functional assemblies, jigs, and fixtures, and many other purposes.

Fictiv has added the following new materials to its collection:

- Nylon 12 Glass-Filled (Duraform GF) for Selective Laser Sintering

- ABS ESD, ASA, PC+ABS, and Polycarbonate (PC) for Fused Deposition Modeling

- Accura 60, Accura Xtreme White 200, and Accura Xtreme Grey for Stereolithography

- Nylon 11 and Polypropylene for MultiJet Fusion

Moreover, Fictiv has expanded the print bed size for its SLS, FDM, and SLA 3D printing technologies. For further information on Fictiv’s new 3D printing materials, please visit the company’s website.

Fictiv serves as an operating system (OS) for custom manufacturing, streamlining the process of sourcing and supplying mechanical parts. With a team of exceptional operations talent, Fictiv’s intelligent OS oversees a network of rigorously screened and managed partners worldwide, providing rapid and high-quality manufacturing services from quotation to delivery. Fictiv has produced over 20 million parts for both startups and established enterprises, enabling them to innovate with flexibility and bring products to the market swiftly.

Source of the story: Fictiv | published on prnewswire

Featured image: Photo by Lucie Siegelsteinová